Did you think that vibration monitoring was only for complex, costly machinery?

Think again.

With PCH Engineering’s affordable range of compact vibration monitors with built-in accelerometers, you can measure and monitor the vibration level of simple rotating machinery without blowing your budget.

Let us explain.

Even simple machine damage can be costly

It used to be that monitoring the vibrations in simple machinery required complex, expensive monitoring solutions, making the investment in such asset protection unprofitable.

Instead, asset owners were forced to rely on manual monitoring and frequent maintenance or run the risk of machine damage.

And that, as any asset owner knows, can turn out to be equally unprofitable.

While simple rotating machinery may be easily repaired or replaced when damaged, the unscheduled maintenance and production stop that result from machine damage and breakdowns can be a costly affair.

Even more so if the machine is critical to production, as waiting for repairs or a replacement can cost plant owners dearly in lost production time.

At PCH Engineering, we wanted to change that. This is what we came up with:

The PCH Compact range – your affordable electronic watch dog

Think of PCH’s compact vibration monitors as electronic watch dogs or vibration switches protecting your machinery from damage and breakdowns:

The compact vibration monitors are a permanent, real-time monitoring solution with built-in sensors, which can be retrofitted to your machines, detecting abnormal vibrations as they occur.

Custom-defined alarm and danger relays reduce the need for human intervention, and scalar values of selected frequency ranges can be used for trending.

And the most important part?

This range comes at a price that makes it a sensible investment, even for owners of simple rotating machinery.

Cost-effective vibration monitors made in Denmark

The compact range of affordable vibration monitors feature internal analogue as well as digital accelerometers, all of which are designed, developed and manufactured at PCH Engineering’s production facility in Denmark.

The PCH Compact Range forms a cost-effective alternative to more complex monitoring solutions for machine owners who wish to protect their simple, rotating machinery from damage and avoid unscheduled production stops.

Collect trend data or perform FFT analyses

Scalar values and real-time time-stream / waveform recordings can be collected using the free PCH Vibration Studio software.

Trend data can also be supplied to existing SCADA or PLC solutions using standard communication protocols like ModBus, TCP, RTU or OPC UA. These data can be made available as 4-20 mA / 0-5V signals or stored locally in a PCH Datalogger module.

When convenient, waveforms can be FFT transformed and analysed on site or remotely.

SIL 2 Rated Vibration Monitors

Most of our monitors are SIL 2 rated with MTTF(D), FIT, PFH(D) and DC diagnostic coverage numbers available.

ATEX Certified Vibration Monitors

Our range of ATEX and IECEx certified vibration monitors (PCH 1275 and PCH 1277) offer vibration monitoring solutions for machines in ATEX zones 1 and 21.

Vibration Monitors for The Eurasian Economic Union (EAC)

We offer versions of PCH 1275 and PCH 1277 that are EAC certified for the Eurasian marked (Russia, Belarus, Kazakhstan, Armenia, and Kyrgyzstan).

And how do we know the compact vibration monitors will work for your machine?

Here is how:

Proven in Use

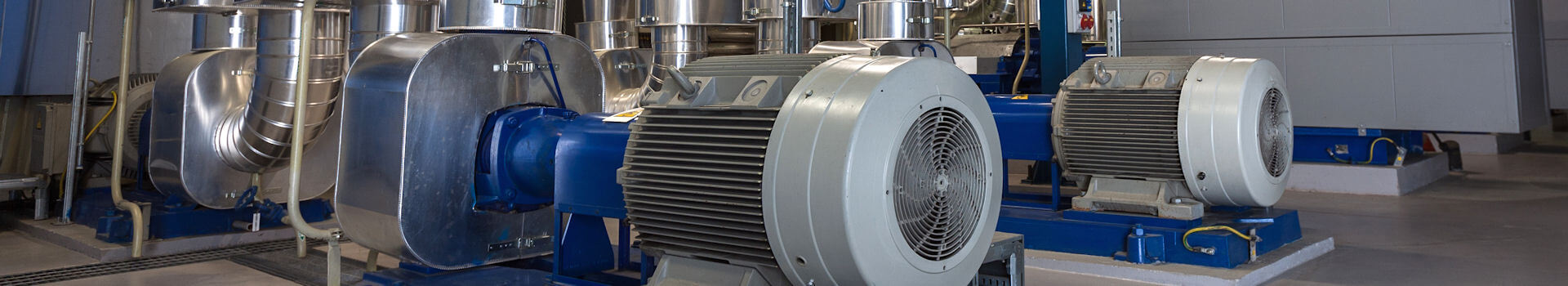

Every year, PCH Engineering outfit approximately 20,000 machines worldwide with vibration sensors, and we supply in bulk for equipment such as:

- Centrifuges, separators, decanters and purifiers

- Gears

- Blowers, fans and pumps

- Spray driers and atomizers

- Cooling towers

- Food & chemical treatment units

- Power plants

- Cement plants

… And any other type of rotating machinery you can think of.

We offer stand-alone solutions as well as solutions for multiple machines. Data collection and analysis can be done locally, or data can be made available for remote access or for integration with cloud-based solutions.

Contact our specialists for advice on the right solution for your machinery.

Contact

a consultant