- 6 input channels

- 4 configurable outputs

- Redundant safety relay

- Bearing fault detectors (Envelope, Crest, Kurtosis)

- Advanced local alarms

- Offline FFT analysis

- Cloud data for remote analysis (IoT)

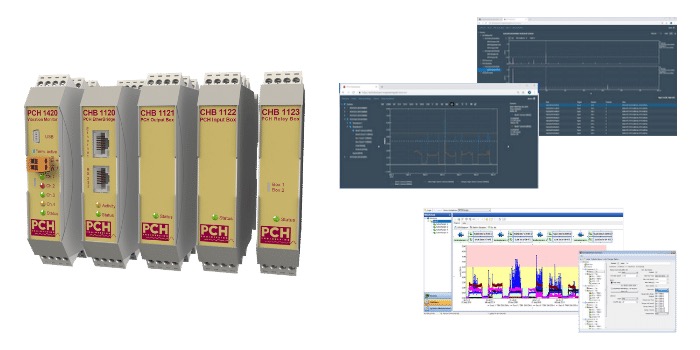

- Part of the PCH Link Concept

Advanced 4-channel vibration monitor

The 4-channel PCH 1420 is an advanced vibration monitor which provides a wide range of real-time vibration data, remote data access and local alarms.

You can use the PCH 1420 vibration monitor as a stand-alone solution or connect it to your SCADA or PLC system.

IoT-enabled condition monitoring solution

PCH 1420 is compatible with our IoT solution,

PCH Cloud. Data from the monitor can be stored in the cloud for remote analysis, making the PCH 1420 a valuable addition to your condition monitoring solution and Industry 4.0 environment.

Contact

a consultant

Main features

- 4 vibration input channels (can also be configured for speed or temperature sensors)

- 1 process input channel

- 1 tacho input channel PNP/NPN/AC, optional 2-wire Namur or negative proximity probe

- 4 configurable outputs: relay, 0/4-20 mA, or 0/2-10 V

- Redundant SIL 2 safety relay

- User defined bandpass filters from 0.7 Hz up to 11,500 Hz

- Bearing fault detectors: Envelope, Crest and Kurtosis

- Adjustable alarm levels and delay times

- Time waveform recordings of vibration sequences from four channels simultaneously

- Offline FFT analysis

- Connection to several accessory boxes on bus system

- USB/RS 485 serial connection

- ModBus TCP via the PCH EtherBridge; Profinet is optional

Versions

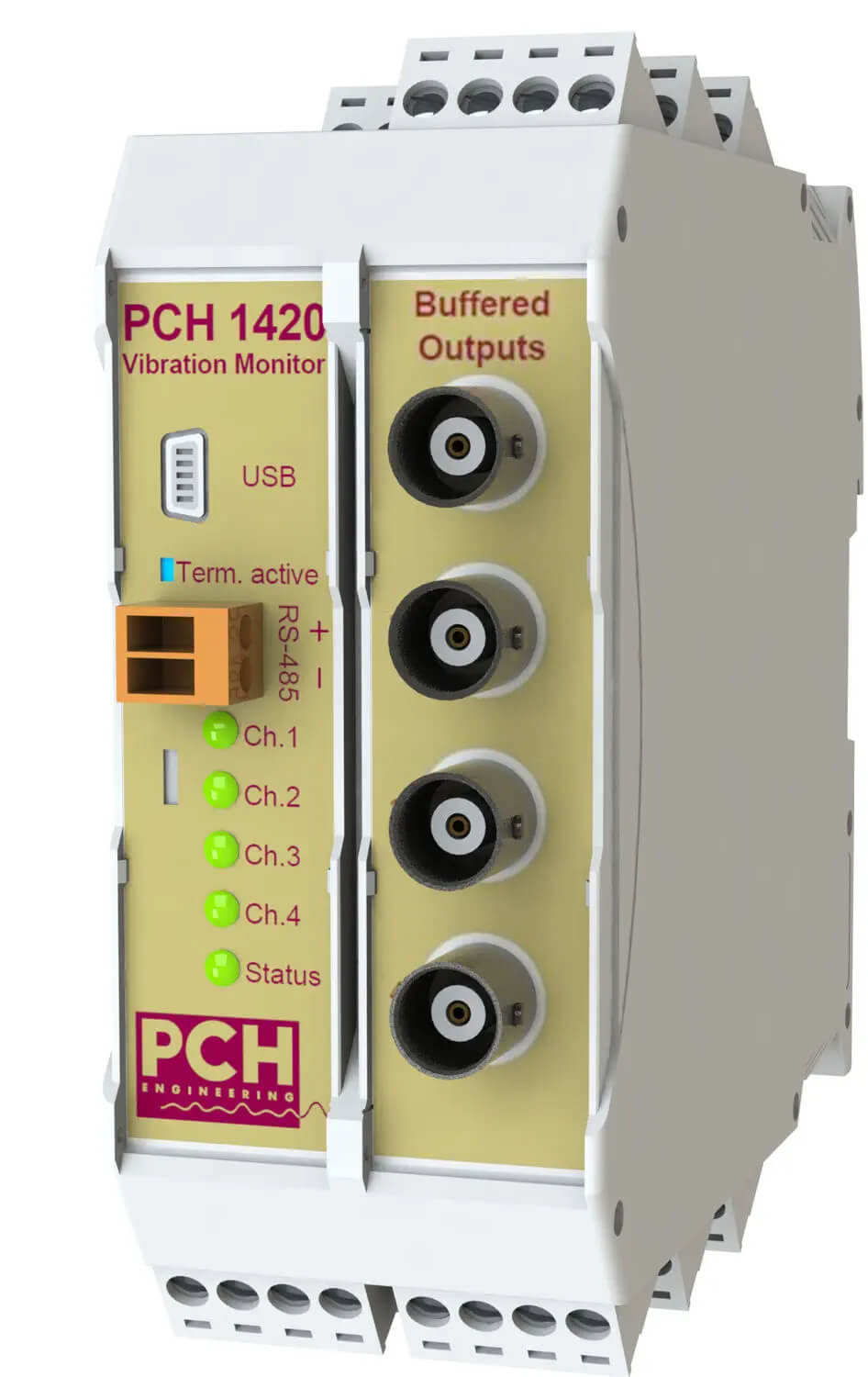

PCH 1420 with buffered outputs

This version of the PCH 1420 vibration monitor comes with isolated, buffered outputs in one, compact unit.

With this version, you get all the benefits of the PCH 1420 vibration monitor's twenty-four-hour asset protection while seamlessly collecting raw, buffered time waveform data from the sensors - accelerometers or eddy current probes - connected to the buffered outputs.

PCH 1420 with buffered outputs has four BNC vibration outputs on the front as well as from the screw terminals for each vibration input channel and for the speed sensor. You can use portable vibration equipment to collect data while simultaneously storing data in your condition monitoring system through a hardwired connection to the screw terminal outputs.

At the screw terminals, the buffered output from the speed sensor can work as a trigger for portable equipment in phase analysis and balancing. This is especially handy if the sensors are positioned in hard-to-reach areas.

PCH 1420 2-channel vibration monitor with optional metal casing for IP68 protection

This version of the PCH 1420 vibration monitor has only two input channels, but is otherwise identical to the standard 4-channel monitor.

It can be hermetically sealed in a protective metal casing that increases its IP rating from IP20 to IP68, making it suitable for mounting in wet and dusty environments.

Only pay for the monitoring solution you need

There is no sense in investing in a complex vibration monitoring system if you only need a few of its functions.

That is why we have made the PCH 1420 Vibration Monitor part of the modular PCH 1420 Link Concept.

With the Link Concept, you can add additional monitoring modules as your need for more sensors grows. In other words, you only pay for what you require here and now.

Applications

The PCH 1420 is an advanced 4-channel monitor suitable for monitoring vibrations in traditional industrial environments as well as Industry 4.0 environments.

It can be used to monitor vibrations of critical assets such as:

Functionality

The PCH 1420 vibration monitor gives you thorough insights into the condition of your machinery, helping you prevent serious machine damage and costly production stops.

This vibration monitor is the sensible choice when you wish to combine machine protection with the condition monitoring of roller bearings.

The PCH 1420 is a volatile 4-channel vibration and process system for the permanent monitoring of vibrations and process parameters in rotating machinery.

Integration to existing condition monitoring systems

Easily integrate the monitor with your DCS, SCADA system or PLC through hardwired 4-20 mA signals, alarm relays or various interfaces like Modbus TCP/RTU, ProfiNet, OPC UA or IIoT (REST).

Remote data access with IoT-functionality

The PCH 1420 4-channel monitor offers a broad range of data, making it a valuable addition to your IIoT / Industry 4.0 environment.

Combine it with the

PCH EtherBridge communication module and get online access to all your real-time vibration data in the cloud.

Bearing fault detectors

The PCH 1420 offers both broadband high frequency monitoring, Envelope, Kurtosis and Crest factor for bearing fault detection.

All the detectors run simultaneously and are based on inputs from up to 4 measuring points in real time. Each bearing fault detector can measure the various fault indicators throughout the lifetime of the bearing.

4 input channels, 2 process channel and 1 tacho input channel

The four input channels are factory configured and calibrated prior to delivery. Gain factors are automatically configured with no user action required.

The vibration monitor has one embedded process channel and one tacho input channel. The process and Tacho channels are updated simultaneously with the four vibration input channels.

5 embedded outputs for optimal safety

The vibration monitor has five embedded outputs. Measuring values and alarms can be directed to the four digital outputs.

The fifth output, a redundant mechanical failure relay, will open in the event of missing sensors, sensors being out of range, short-circuits or general monitor errors.

Redundant relay for trip alarms

The monitor design features a redundant isolated system failure relay, which you can use for trip alarms from all measuring bands configured with individual trip alarms.

Self-test procedures

You can also activate a self-test procedure through a digital input or through user software for testing the monitor and the outputs. This ensures a highly reliable data output and reduces the test cycle duration.

Advanced alarm functionality

When an alarm limit is exceeded, integrated alarms alert the user through a connected rotor light, a beeper, a control system, or by directly shutting down the machine.

LED lights on the front of the monitor clearly show the status of the four measuring channels, while a status LED light indicates general errors or failure conditions.

In the event of vibration alarms, the affected channel will turn yellow to indicate the alert level or red to indicate the danger level.

In the event of a sensor error or an overload, the individual LED for the affected channel will flash red, and the status LED will turn permanently red as well. Alarms or input errors from the process inputs will turn the status LED red.

The alarm functions can also be configured as needed.

Complementary software interface for analysis and individual setup

You can use the monitor’s standard setup out of the box or easily adapt the setup to your specific requirements using the PCH Vibration Studio software, which comes complementary with the monitor.

We offer several versions and configurations to provide you with a suitable solution for your specific application.

The complementary PCH Vibration Studio software provides online trending, simultaneous recordings of four time waveform signals (raw data), and an FFT tool for diagnostics and analysis.

The software is user-friendly, and you can connect a USB cable or a permanent RS-485 wire for remote access.

You access the PCH 1420 easily through the embedded USB 2.0 connector on the front of the monitor. The monitor settings are imported to your computer, and you can alter them from here.

The PCH 1420 also offers an RS485 2-wire connection for long distances and can be daisy-chained into a network of monitors.

The RS485 connection is used for the PCH Vibration Studio software and for the optional PCH EtherBridge LAN/TCP module (remote access).

A switch on the front of the PCH 1420 activates an internal 120 Ohms resistor in order to terminate the RS485 network.

Options

Input channels

The PCH 1420 vibration monitor has four input channels. This means it can be delivered for various types of vibration sensors, including:

- IEPE Piezo or 3-wire API 678 accelerometer (negative voltage)

- API 670 proximity probes (negative voltage)

- True Velocity sensors (moving coil technology) ±10V

- PCH Low Frequency MEMS accelerometers

- DC signals like 4-20 mA or 0-2.4/5/10V for process

Speed sensor input

- Configurable speed measurements based on an NPN/PNP sensor or through an AC signal 0-30V (>10V)

- Number of pulses per rotation are user configurable, up to 5000 per second

- Full scale range RPM is user configurable

- Missing pulses can be detected and activate an alarm

- Can be delivered for a proximity probe (Keyphasor) signal as speed input.

Analogue input

- Offers either a 4-20 mA or a 0-2.4/6/12/24 VDC input signal

- Configurable Full Scale and measuring units

- NAMUR NE43 monitoring for missing input signal

- Can be delivered for a proximity probe for axial displacement measurements (GAP)

5 configurable outputs

Measuring values and alarms can be directed to the monitor’s four digital outputs. They can be user configured as:

- 0/4-20 mA or 0/2-10 V outputs

- NPN relay driver for a separate relay

- Digital Input directly to a PLC.

The fifth output, the redundant mechanical failure relay, can be configured for vibration and process alarms.

Individual setup of channels, accelerometers/velocity sensors

All measuring- and process channels can be individually configured by the user. For a typical accelerometer vibration input channel, you can configure:

- 2 active measuring bands per accelerometer

- Filter ranges from 0.7 to 11500 Hz

- Measuring units: Acceleration, Velocity or Displacement

- Detector as true RMS with adjustable averaging time, Peak and Peak-to-Peak. You can freely adjust the Peak detector with Attack and Decay times.

- 2 alarms per measuring band: Alert (pre-warning) and Danger (trip) alarms can individually be configured incl. delay times of up to 100 seconds.

If you need several measuring bands and fewer accelerometers, more channels can be connected to the same accelerometer. This setup is useful for monitoring individual gear mesh frequencies (GMF).

Individual setup of channels, proximity probes (eddy current probes)

Up to four factory-configured, negative input channels (-24V) can be individually configured by the user. Various sensitivities are supported:

- Filter ranges from 0.7 to 11,500 Hz

- Measuring units Displacement as mils, µm or mm

- Detector as true RMS with adjustable averaging time, Peak and Peak-to-Peak. You can freely adjust the Peak detector by Attack and Decay times

- 2 alarms configurable: Alert (pre-warning) and Danger (trip) alarms can be individually configured incl. delay times of up to 100 seconds

- DC monitoring / GAP monitoring for actual position of the probe tip

- 4 alarms configurable for GAP monitoring

The individual probe sensitivity as well as the linear range can be user configured.

Configurable alarm settings

Alert (pre-warning) and Danger (trip) alarms can be configured for each measuring band and process input.

The Danger alarms can be guided to the mechanical SIL 2 relay for a single signal in the event of high vibration levels, or to the digital outputs if configured as a relay.

A PCH Relay Box can be added for up to 12 extra mechanical relay outputs as part of the PCH Link Concept.

All alarms can be latched for a manual reset and, if not in use, the alarms can be held (Alarm Hold), allowing the controller time to react (0-100 s in 0.1 s steps).

You can configure the alarms as either High Level Alarms or Low Level Alarms (the alarm will alert the operator if vibrations higher than X and/or lower than Y are detected).

Inhibit functions for NO-TRIP due to resonances

Resonances often occur in machines during certain stages such as run-up and coast-down. If so, you can inhibit the alarms either through a digital input signal or by using one of the process inputs.

For instance, if you know your machine will resonate and create strong vibrations during run-up, you can inhibit the alarms within that specific rotating speed, e.g. 500-700 rpm or higher for a turbine.

You can freely configure the inhibit window using the complementary software,

PCH Vibration Studio.

Compliance

ISO 10816/20816 compliant 4-channel monitor

The 4-channel PCH 1420's standard setup is ISO 10816/20816 compliant. It can help you detect early bearing faults while monitoring the severity of unbalance and misalignment in your machinery.

EN/ISO 13849-1 Functional Safety

The standard PCH 1420 supports Functional Safety requirements according to ISO 13849-1. The PCH 1420 monitor meets the Performance Level d (PLd) and can be used in a SIL 2 measuring chain.

SIL 2 rated 4-channel monitor

The four-channel PCH 1420 vibration monitor is SIL 2 rated and can form part of a SIL 2 safety chain as well as a condition monitoring system.

Contact

a consultant

This version of the PCH 1420 vibration monitor comes with isolated, buffered outputs in one, compact unit.

This version of the PCH 1420 vibration monitor comes with isolated, buffered outputs in one, compact unit. This version of the PCH 1420 vibration monitor has only two input channels, but is otherwise identical to the standard 4-channel monitor.

This version of the PCH 1420 vibration monitor has only two input channels, but is otherwise identical to the standard 4-channel monitor.

Download product data sheet

Download product data sheet See all vibration monitors

See all vibration monitors Learn more about PCH Cloud and IoT condition monitoring

Learn more about PCH Cloud and IoT condition monitoring