Protect your critical assets with our cost-effective vibration monitoring system

Even a few hours’ unscheduled downtime in critical machinery can mean a great loss in production and man hours – not to mention the cost of repairs and spare parts when machinery is damaged.

Detect misalignment and bearing faults in rotating machinery

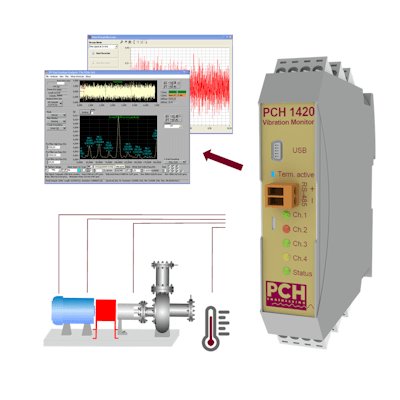

By monitoring vibrations in your rotating machinery, you get early warning of any misalignments or bearing faults.

The PCH vibration monitoring system protects your machinery 24/7. This helps prevent machine breakdowns and ensures continuity of production.

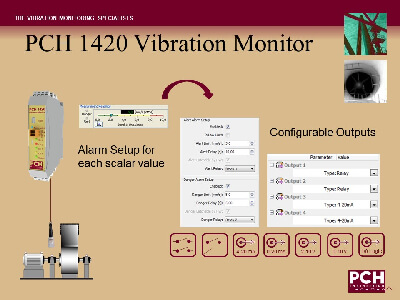

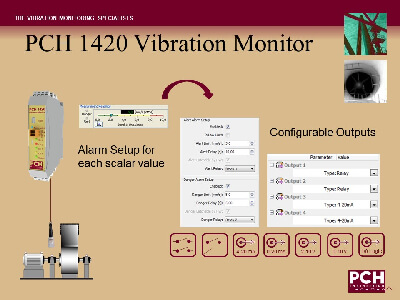

Local safety with built-in alarms

The slightest imbalance or misalignment can cause great damage to a machine and its bearings.

That is why our vibration monitors have a built-in alarm function which can detect any machine faults and warn the operator before they cause breakdowns.

You can even configure an automatic shut-down function for added local safety.

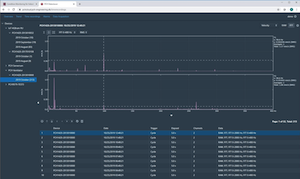

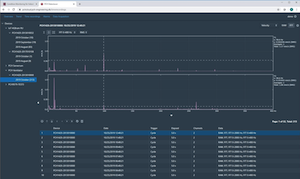

Collect trend data and perform FFT analyses

Collect trend data and perform FFT analyses

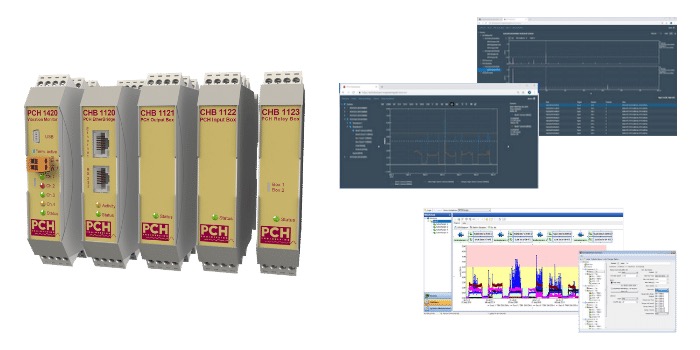

The PCH vibration monitors are the perfect addition to your condition monitoring or predictive maintenance program. You can collect scalar values and real-time time-stream / waveform recordings with the complementary PCH Vibration Studio software.

You can also transfer data to a SCADA or PLC solution using communication protocols like CAN Open, ModBus or ProfiNet, made available as 4-20 mA / 0-5V signals.

Store vibration data locally or online

Store the data locally with a PCH Datalogger module or our OPC server, or send it to a cloud database for remote access.

It is possible to make a fourier transformation (FFT) of time-recordings and identify vibration frequencies affecting your machine performance.

The analysis can be done on site or at a remote location after data transfer using our PCH EtherBridge.

Data can be treated locally or in the cloud. You retain ownership of your vibration data at all times.

Compact vibration monitors and ATEX certified monitors

With our affordable range of compact vibration monitors, you can measure and monitor the vibration level of simple rotating machinery without blowing your budget.

Also find ATEX certified vibration monitors here.

See the full compact range

IoT-enabled vibration monitors

Ready your machinery for Industry 4.0 with PCH Cloud.

PCH Cloud is the first condition monitoring solution with vibration data in real time.

Get the safety of a traditional vibration monitoring solution combined with the optimisation potential of a smart factory condition monitoring solution.

Explore the PCH Cloud solution Redundant vibration sensors.jpg)

When full redundancy is legally required for your machinery, and you want a simple vibration monitoring solution, what you need is a redundant vibration monitor with two fully separated, parallel measuring channels with individual vibration sensors.

See our simple redundant vibration monitors here Proximity probe monitors

Proximity monitors are ideal for measuring shaft rotation in moving targets such as turbines, rotary atomizers and other machinery with sleeve bearings.

All PCH Proximity Probe Monitors measure the dynamic vibrations as well as the GAP distance to target.

Find your proximity monitor here

Sound monitors.png)

Use the permanent sound monitor to monitor the noise level of traffic, airports, discotheques, working areas and other environments subject to noise restrictions.

Learn more about sound monitoring here

Which vibration monitor should you choose?

When choosing your monitor, note the combination of vibration input channels and relays or configurable outputs.

Each PCH vibration monitoring device comes with complementary,

Windows-based software for parameter set up, time wave streaming and offline FFT.

Several monitors also feature RS-485 communication.

Not sure which vibration monitoring solutions is right for you?

Our consultants

are here to help

.jpg) Your trusted partner in machine protection

Your trusted partner in machine protection

You can safely rely on the expertise of PCH Engineering A/S.

We have close to 30 years of experience with vibration monitoring equipment, and we supply vibration monitoring equipment and solutions for approximately 20,000 machines annually.

We specialise in tailored monitoring solutions for original equipment manufacturers. We also supply small and large enterprises with out of the box or customised vibration monitoring equipment.

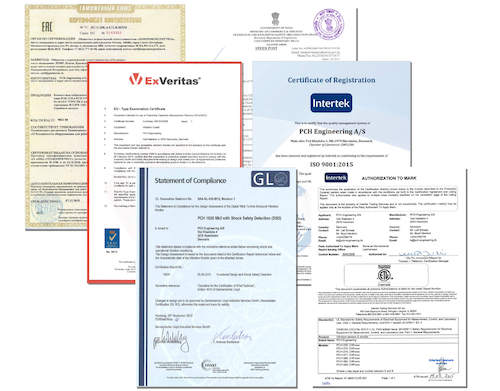

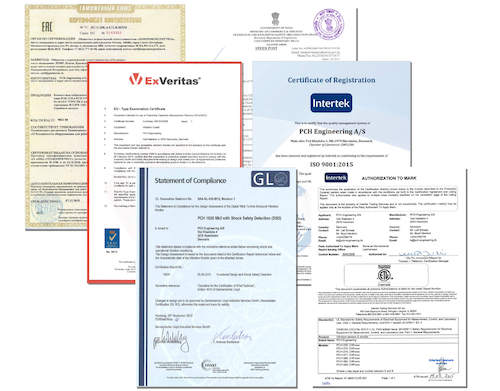

Fully certified monitors and sensors made in Denmark

Fully certified monitors and sensors made in Denmark

All PCH Engineering's vibration monitors and sensors are developed and produced in Denmark by our experienced engineers.

Our company and product certifications include:

- CE

- ISO

- ATEX/IECEx

- GL

- UL 61010-1:2012

This is your guarantee that the equipment meets all international regulatory and quality standards.

Contact

PCH Engineering

Collect trend data and perform FFT analyses

Collect trend data and perform FFT analyses

.jpg)

.png)

Industries

Industries

.jpg) Your trusted partner in machine protection

Your trusted partner in machine protection Fully certified monitors and sensors made in Denmark

Fully certified monitors and sensors made in Denmark